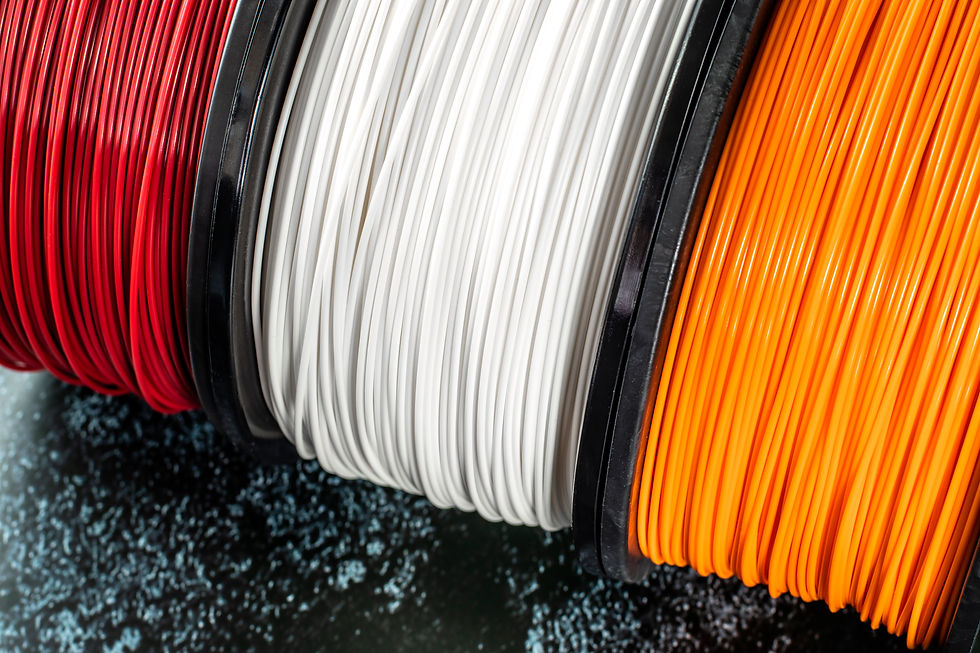

Using Poor or Cheap Filament

- Joe Coogan

- Jan 30

- 2 min read

Using poor or cheap filament in a 3D printer can lead to several issues that affect print quality, printer longevity, and overall efficiency.

Here’s a breakdown of potential problems and how to mitigate them:

1. Print Quality Issues

Inconsistent Diameter: Cheap filaments often have variations in diameter (e.g., ±0.1mm or more instead of ±0.02mm), leading to extrusion inconsistencies, under-extrusion, and layer gaps.

Poor Adhesion: Some budget filaments don’t adhere well to the print bed or between layers, causing warping and weak prints.

Excessive Stringing & Blobbing: Impurities and additives in low-quality filament can cause uncontrolled extrusion, resulting in stringing and blobs on prints.

Color and Finish Issues: Inconsistent pigment mixing can lead to patchy or faded colors.

2. Printer Clogging & Maintenance Problems

Nozzle Clogs: Poorly made filaments may contain dust, dirt, or oversized particles, clogging the nozzle and requiring frequent cleaning or replacements.

Increased Wear on Components: Some budget filaments have unregulated additives that can accelerate wear on brass nozzles, extruder gears, and PTFE tubes.

Inconsistent Flow Rate: Variations in filament density and quality can cause extruder skipping and uneven layer deposition.

Can lead to blocked Nozzels and a ball of welded material around the print head leading to and expensive repair.

3. Mechanical & Structural Weakness

Brittle Prints: Cheap filaments often use subpar plastic mixtures, leading to brittle prints that snap or break easily.

Lower Heat Resistance: Some low-cost PLA or PETG filaments soften at lower temperatures, making them unsuitable for functional parts.

Warping & Shrinking: Inconsistent formulations can cause excessive warping, particularly with ABS or PETG.

4. Environmental & Health Risks

Toxic Additives: Some low-cost filaments may include harmful chemicals or heavy metals, which could release unsafe fumes when printing.

Poor Packaging & Moisture Absorption: Budget filaments are often poorly vacuum-sealed, allowing moisture absorption that leads to print defects and extruder issues.

5. Waste of Time & Material

Failed prints due to adhesion issues or weak filament often lead to wasted material, printer downtime, and frustration.

How to Avoid Issues with Cheap Filaments

Stick to Reputable Brands: Brands like Creality, Eckoo, eSun, Polymaker, or filament by your printer manufacture offer good balance between affordability and quality.

Check Tolerances: Look for a filament with a diameter tolerance of ±0.02mm.

Buy Properly Sealed Filaments: Ensure the filament is vacuum-sealed with desiccant to prevent moisture issues.

Perform Test Prints: Run small calibration prints before committing to a large project.

Store Filament Properly: Use airtight storage with silica gel to maintain quality or ideal in a Drybox Cabinet.

Comments